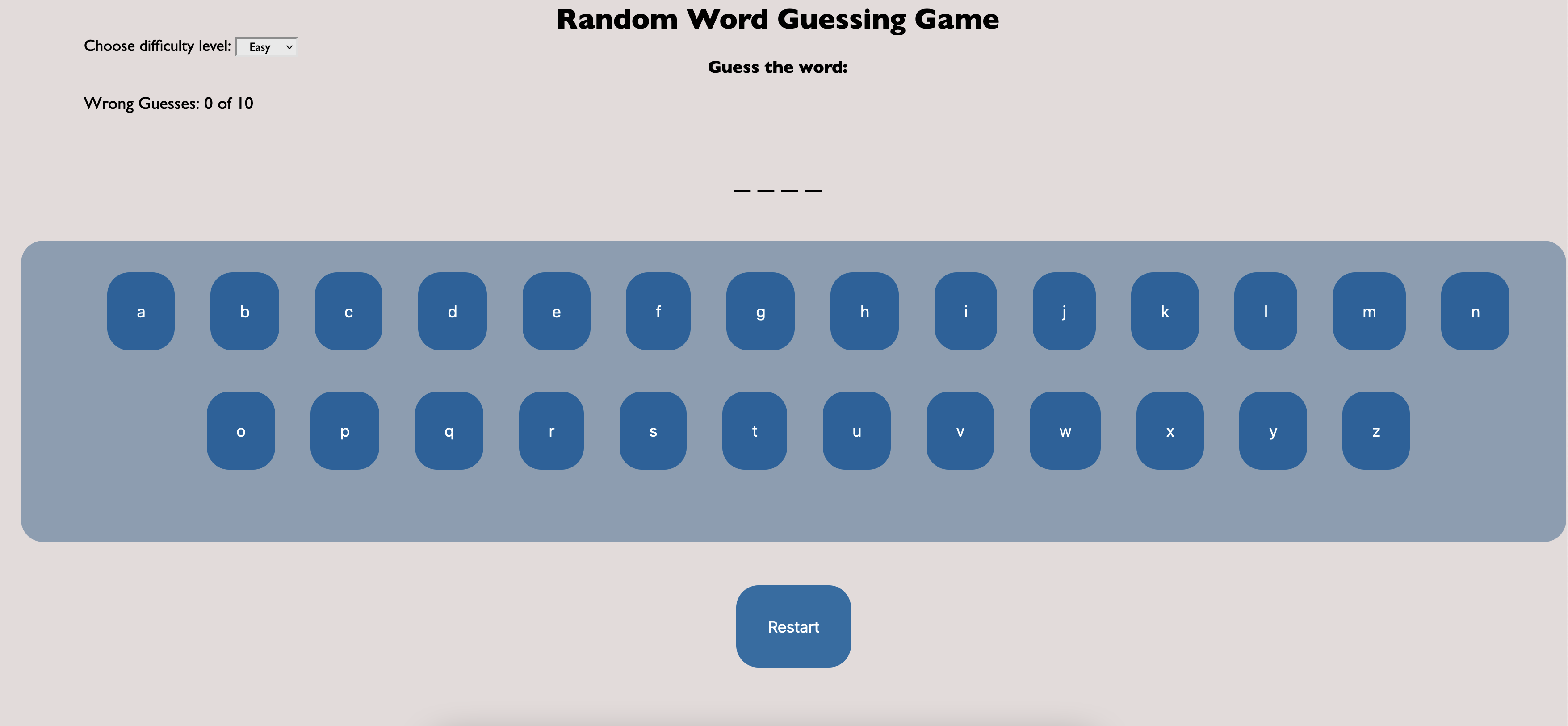

Soundwave Art Installation

I conceptualized, designed, and built a large-format, wall-mounted wood art installation from scratch, translating a digital soundwave into a physical piece using hand-selected materials and custom tooling solutions.

Process Overview

User-Centered Design:

The piece was created with specific dimensions (3’ x 6’) to meet space constraints, and the soundwave featured a meaningful phrase selected for emotional resonance—anchoring the work in user-centered principles.

Material Selection:

Chose Alder wood for its regional relevance (native to the Pacific Northwest), moderate weight (important for wall-mounting), and strong workability—balancing aesthetics, function, and material science.

Digital-to-Physical Translation:

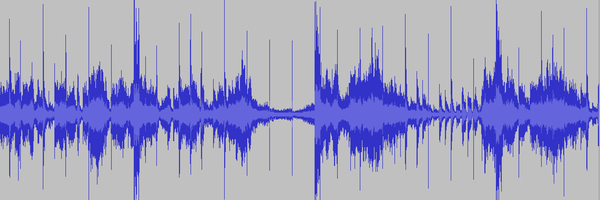

- Captured and isolated audio using Audacity®.

- Exported soundwave as a scalable PNG using GIMP

- Converted to a full-size physical template using large-format printing

Tool Customization:

Designed and fabricated a custom zero-clearance insert and hold-down jig for the table saw using phenolic resin and a router to enable safe, consistent cutting of 1/8” wood strips—demonstrating tool adaptation and process optimization.

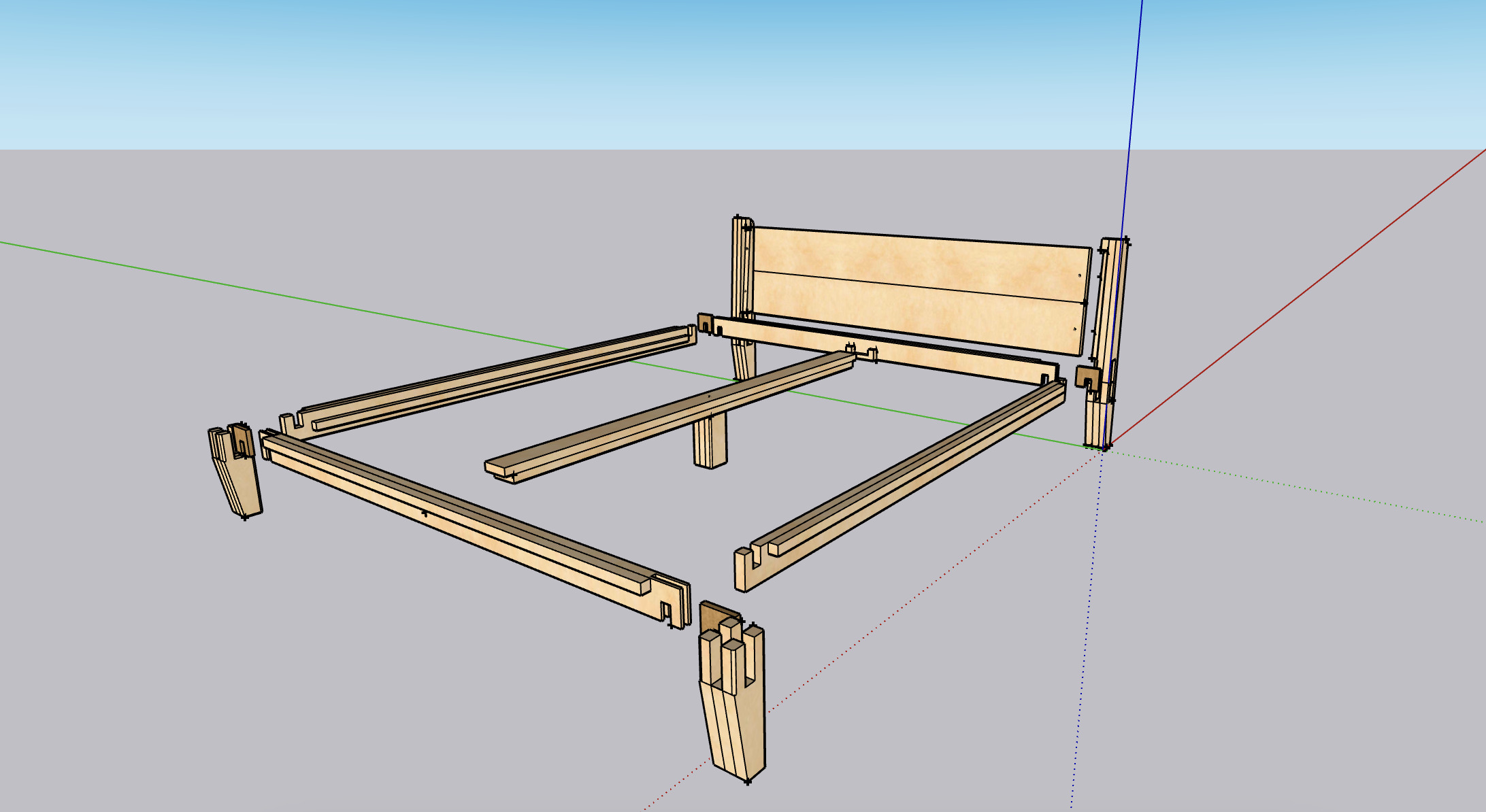

Staged Build Process:

- Glued and planed panels for the base

- Aligned thin strips over the template to form the waveform

- Used fast-setting adhesives, sanding, and sectional glue-ups to ensure precision and finish quality

Aesthetic Finishing:

- Applied layered gradient stain using MIXOL® pigments with denatured alcohol

- Sealed the piece with polycrylic, then hand-buffed with Scotch-Brite for a high-gloss finish

Skills Demonstrated:

- End-to-end project planning & execution

- Tool customization & hands-on problem-solving

- Strong visual communication & technical documentation

- Translating abstract digital inputs into high-fidelity physical output

- Focus on user/audience experience and design resonance